For more than 50 years, Prensoland’s block making machines are highly valued in the international market for production of concrete products. The most positive aspects that customers highlight of our machinery are rugged construction, easy handling, versatility, high quality of the final product and profitability overall.

Profitability is a key aspect for our customers and our R & D is completely aware of it. For this reason, we constantly research to further improve the quality of production and exceed all industry expectations. Also, we design block making machines models fully adapted to the customer, in order to provide optimal productivity in all markets of the world.

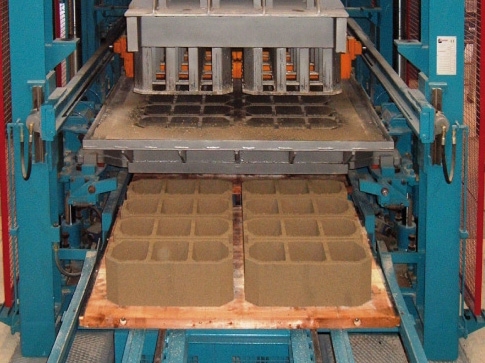

In the following presentation, we have calculated the productivity of all Prensoland’s block making machines models, indicating the number of parts produced per cycle and time, in a standard 1400 mm wide / 750 mm deep pallet. We have relied on universal pieces: uni pavers, uni pavers face mix, kerbs, kerbs face mix, American blocks, infill blocks. However, our block making machines’ possibilities are endless in production of special pieces. It is also important to note that we have made this calculation based on a 100% press performance.