A great advantage of our Paver block making machines range

Compacta is its versatility.

Prensoland block making machines, with extractable moulds, manufacture a large number of pieces using different types of concrete, enabling the company to offer construction or application based solutions. An example of this is surface paving, where, increasingly, the use of pavers has gained ground due to their enormous potential.

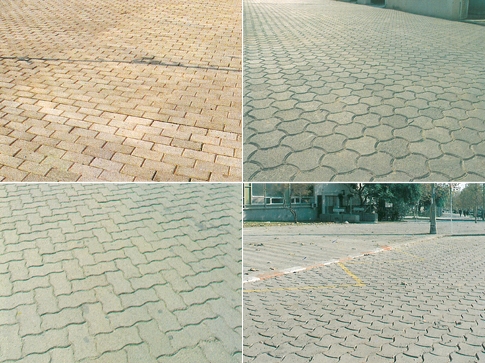

Using pavers opens up new possibilities for laying pavements. Pavers have great aesthetic potential as they are symmetrical and create uniformity on the road, and are available in a wide range of shapes, designs and colours. Concrete pavers are hardwearing and resistant to damage caused by traffic and the weather. It is also important to note their price (they are less expensive that other traditionally-used systems), the straightforward method used for laying them and their adaptability to the road.

Different types of standardised pavers currently exist and, usually, the type of paver used depends on paving requirements. One of the main types of pavers used is the Bétulo paver, which is rectangular shaped and was designed especially to replace the classic stone paver. The Bétulo paver is economical, easy to lay and offers a perfect finish, ensuring that surfaces are uniform. It is generally used for paving in gardens, squares and suburban neighbourhood districts.

Another type of paver is the Uni paver, which has an undulated shape. This paver provides flexibility in paving and can be used to distribute loads gradually while also enabling different types of fittings. It is designed especially for areas of dense traffic.

Lastly, another type of paver currently in use is the Trief paver. Its triangular shape means that it is a high-resistance paver, enabling efficient weight distribution. It is a robust paver that can be disassembled and reused due to its dry-lay system. It is ideal for places where heavy traffic is continuous, such as petrol stations, bus stops, port areas and airport runways.